PDF(615 KB)

PDF(615 KB)

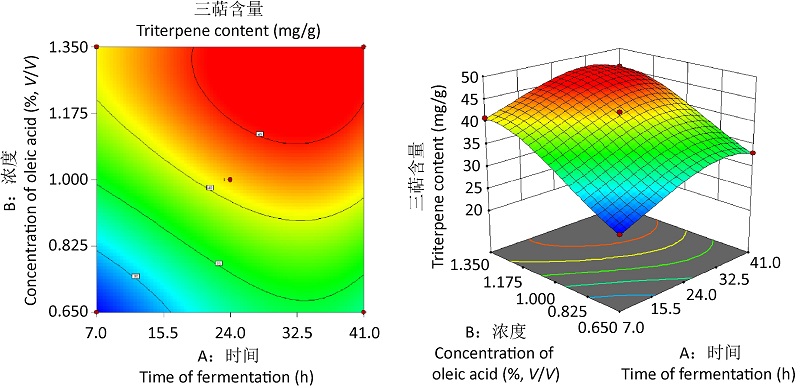

油酸促进灵芝三萜液态深层发酵的工艺研究及规模化验证

苏晓薇,唐庆九,张劲松,冯娜,王金艳,周帅,冯杰,俞苓

菌物学报 ›› 2021, Vol. 40 ›› Issue (9) : 2445-2460.

PDF(615 KB)

PDF(615 KB)

PDF(615 KB)

PDF(615 KB)

油酸促进灵芝三萜液态深层发酵的工艺研究及规模化验证

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Synthesis of triterpenes in liquid submerged fermentation of Ganoderma lingzhi promoted by oleic acid

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

/

| 〈 |

|

〉 |